Polyol und Isocyanat für die Keilschuhsohle der Dame

Holen Sie sich aktuelle Preis| Zahlungsart: | L/C,T/T,D/P |

| Incoterm: | FOB,CFR,CIF |

| Minimum der Bestellmenge: | 1000 Kilogram |

| Transport: | Ocean |

| Hafen: | Shanghai |

| Zahlungsart: | L/C,T/T,D/P |

| Incoterm: | FOB,CFR,CIF |

| Minimum der Bestellmenge: | 1000 Kilogram |

| Transport: | Ocean |

| Hafen: | Shanghai |

Modell: XC-9080W/XC-6088W

Marke: Xuchuan Chemical

Herkunftsort: China

Application: Outsole, slippers, wedge shoes

Code: XC-9080W/XC-6088W

Keywords: water soluble polyurethane resin

Appearance: Liquid

Characteristic: Low density and high hardness, good appearance, little pinhole, and weak foam line

| Application | shoe sole |

| Keywords | water soluble polyurethane resin |

| A/B Materials Temperatures(℃) | A/B Materials Temperatures(℃) |

| A+C/B Mix ratio (By weight) | 100/100~102 |

| Cream Time (s) | 6~8 |

| End of Rise Time (s) | 30~40 |

| Free Rise Foam Density(g/cm3) | 0.21~0.26 |

| Mold Temperature(℃) | 45~55 |

| Demold Time(min) | Demold Time(min) |

| Molded Density (g/cm3) | 0.35~0.60 |

|

Characteristic: Low density and high hardness, good appearance, little pinhole, and weak foam line |

|||||||

|

Application: Outsole, slippers, wedge shoes |

|||||||

|

Typical properties of PU matrix |

|||||||

|

Name of products |

Appearance |

Viscosity (mPa·s/40℃) |

Density (g·cm-3/40℃) |

Package(kg) |

/ |

/ |

/ |

|

A-9080W |

Cream,White,liquid |

1000~1300 |

1.01~1.02 |

18 |

/ |

/ |

/ |

|

B-6088 |

Yellowish transparent liquid or waxy |

600~800 |

1.08~1.2 |

20 |

/ |

/ |

/ |

|

Materials preheat |

|||||||

|

A-9080W: preheated at 50~60℃ for 6~8 hours. |

|||||||

|

B-6088: preheated at 50~60℃ for 6~8 hours. |

|||||||

|

Typical processing parameters & Reaction parameter. |

|||||||

|

Items |

A/B Materials Temperatures(℃) |

A+C/B Mix ratio |

Cream Time (s) |

End of Rise Time (s) |

Free Rise Foam Density(g/cm3) |

Mold Temperature(℃) |

Demold Time(min) |

|

Parameter |

40~45/38~42 |

100/100~102 |

6~8 |

30~40 |

0.21~0.26 |

45~55 |

5~7 |

|

The adding content of C-2 should be 210g±10g/18kg. |

|||||||

|

The adding content of water should be 0~80g/18kg according to the reality. |

|||||||

|

The adding content of hardener should be 0~1200g/18kg according to the reality. |

|||||||

|

Physical propertiesShoe Sole Pu Chemical |

|||||||

|

Items |

Molded Density (g/cm3) |

Hardness |

Tensile strength |

Elongation |

Tear Strength |

Williams abrasion |

/ |

|

Physical properties |

0.35~0.60 |

60~88 |

4~7 |

200~300 |

11~20 |

130~200 |

/ |

|

Demold time may be prolonged with the increase of sole thickness. |

|||||||

|

|

|||||||

|

|

|||||||

Diese physikalischen Daten werden erfasst, indem eine Probe von 6 mm dickem Testen getestet wird.

Die oben aufgeführten Daten dienen nur als Referenz. Die Detaildaten werden praktischer Produktion unterzogen. Wenn andere Anfragen nach physischen Eigenschaften, kontaktieren Sie uns bitte.

PU -System für Schuhsohle, Klebstoff für Schuhe, CPU, TPU, Polyester Polyol, PU -Harz für Tinte, Pur Heißem Schmelzekleber, Klebstoff für flexible Packungen, PU -Harz für synthetisches Leder

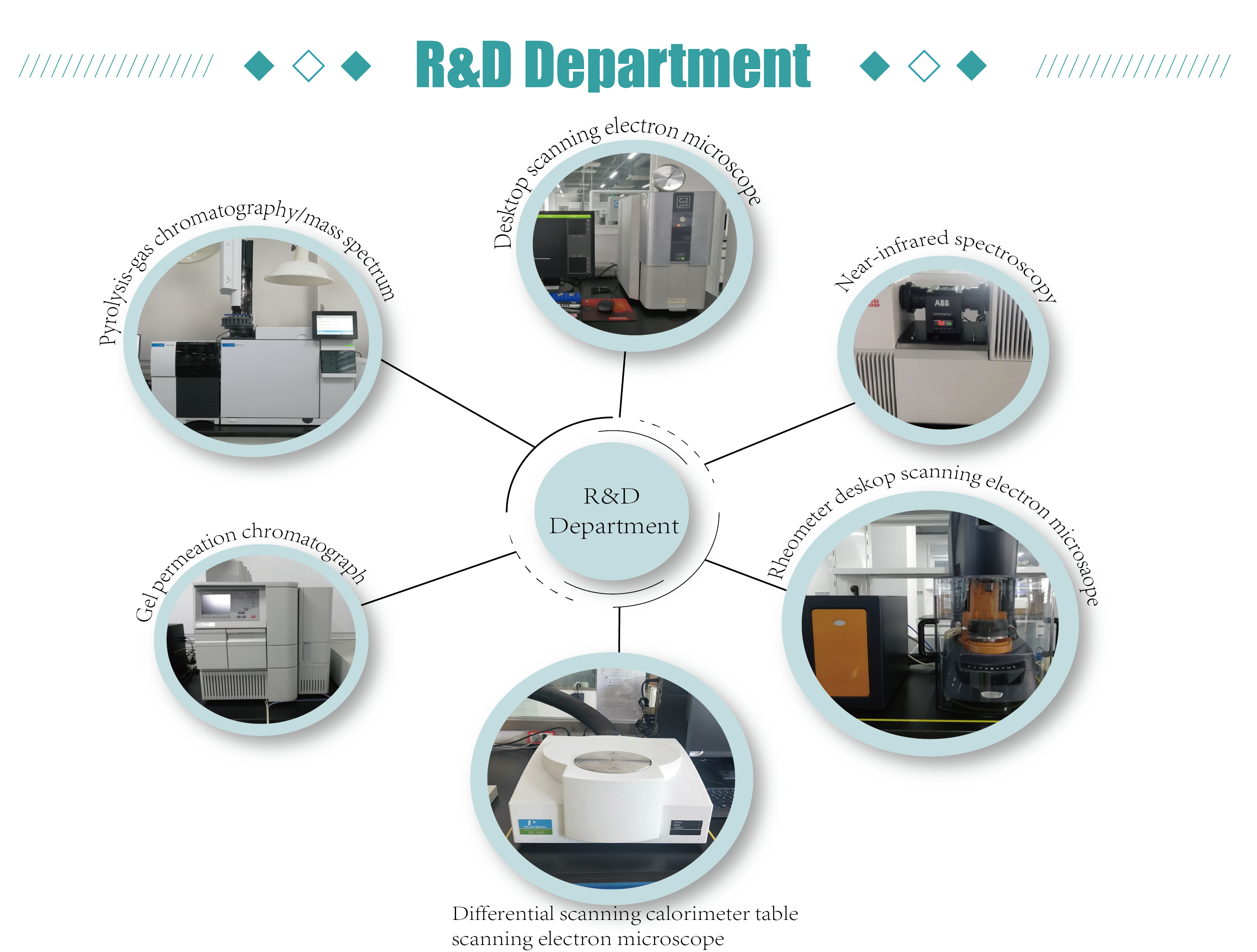

Xuchuan Chemical, das 2007 gegründet wurde, beträgt das Unternehmen ein registriertes Kapital von 500 Millionen RMB. Die Hauptprodukte sind alle Ranges Polyester Polyol, Polyurethanharz für Schuhe, Wasserbasis und lösungsmittelfreie Polyurethanharze für künstliches Leder, Polyurethan-Bindungsklebstoffe und Heißschmelzklebstoffe mit Polyurethan.

Jetzt verfügt Xuchuan über 4 moderne Produktionsbasis, die Produktionskapazität erreichte 630.000 Tonnen pro Jahr, Produkte wurden in 32 Länder und Regionen der Welt exportiert.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.